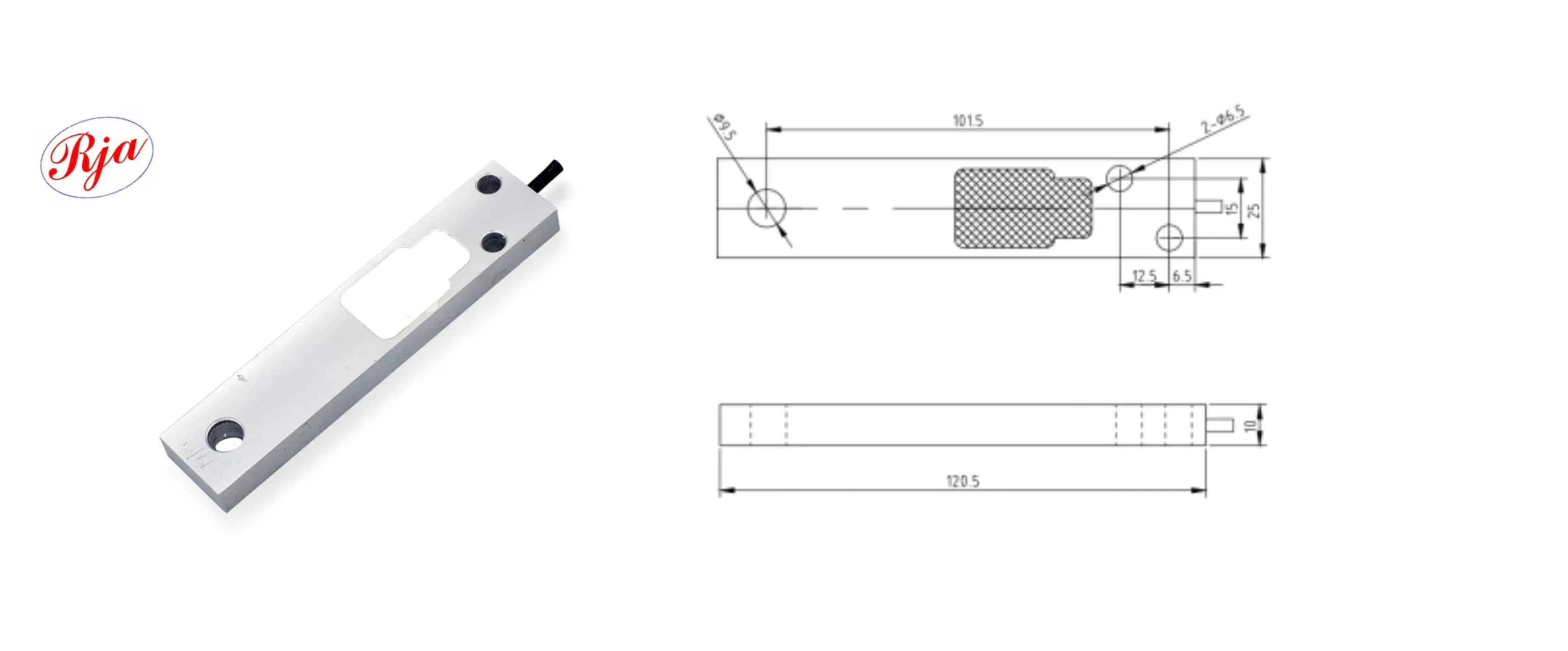

RJ-6525 Force Sensor Simple Structure high quality Force gauge compression load cell

Principle and Structure:

Elevator load sensors, integral to safety and operational integrity, serve as pivotal weigh stations monitoring the dynamic payload within the elevator car to avert overloading hazards. Operating on the fundamental principle of strain gauge technology, these devices undergo a measurable change in resistance when the sensing element deforms under applied load. Upon ingress of passengers or freight, the load is transferred to the sensor, inducing a deformation proportional to the exerted force. This deformation precipitates a variation in electrical resistance, which is then transduced into an analog or digital signal by the sensor's sophisticated circuitry.

The resultant signal is meticulously analyzed by the elevator's advanced control system, endowed with the capability to ascertain if the cumulative weight surpasses the predetermined safety threshold. Upon identifying an overload condition, the system promptly initiates a safety protocol, inhibiting door closure and elevator motion, thereby compelling passengers to alleviate the excess load. This preemptive mechanism not only safeguards passenger welfare but also enhances the longevity of the elevator's mechanical components by mitigating undue stress beyond its engineered specifications. Incorporating state-of-the-art digital sensors, modern elevators exhibit heightened precision and reliability, facilitating a secure and efficient vertical transit experience. Elevator load sensors are thus paramount in upholding stringent safety benchmarks and regulatory adherence within the ambit of building management systems

ELEVATOR LOAD CELLS PRODUCT FAMILY(25-1000KG)

Mounting Type

ESAY INSTALL

Description

Precision Load Cell Senor

Series

evevator lifts load cell family

Features

High precision good performance

Place of Origin

Shaanxi, China

Accuracy class

C3 Excluded

Our company takes product technology as guide, cooperates with partners confidentially, and strives to become your better supplier with perfect after-sales service as its guarantee.Since our company began to study resistance strain gauge in 1997, it has continuously pursued technological innovation and developing and producing in strict accordance with the 0IML62# recommendation and GB/T13992-92 standard. Our company employs several senior members of the strain gauge industry as the technical consultant for many years, and has more than 20 years of technical and technological personnel engaged in the industry, so as to ensure the long-term stability and consistency of our products.For many years, our company has been strengthening its cooperation with research institutions in polymer material industry to develop base materials which suitable for high-quality resistance strain gauge. The strain gauge produced by our company is suitable for manufacturing medium-precision and high-precision weighing load cells and precision stress analysis, greatly reducing the lag and non-linear error of products and improving the stability of the product.

1.What's your MOQ?

Normally our MOQ is 100 pcs, but sometimes maybe we have other order on hand, if based on ODM, MOQ can be negotiated.

2.Are you a trading company?

We are manufacturer, our factory has passed CTI, ISO9001:2008, NTEP, OIML, we have good quality control.

3.Do you accept customized?

Yes, we have different customers make their own OEM products.

So we also can make products as per your requirement.

4.How long can I expect to receive my goods after I place an order?

Our production time is always 45 days after pre-production sample confirmation.

5.Can I get some samples before place order and how long for a sample?

Yes, but customer needs to pay for the samples and freight,the lead time for samples is about 7 days up on got the payment.

6.How is your shipping?

1)shipping by express(sample order) or by sea (bulk order);

2)worldwide shipping service available;

3)please contact before order as shipping cost varies time to time.

7.Will you have some discount?

1)To clients who bring repeat orders and large orders;

2)Please contact us for Better Quote.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!